Cost Reduction Exercise at Quarry, Mining & Construction OEM

Project Summary

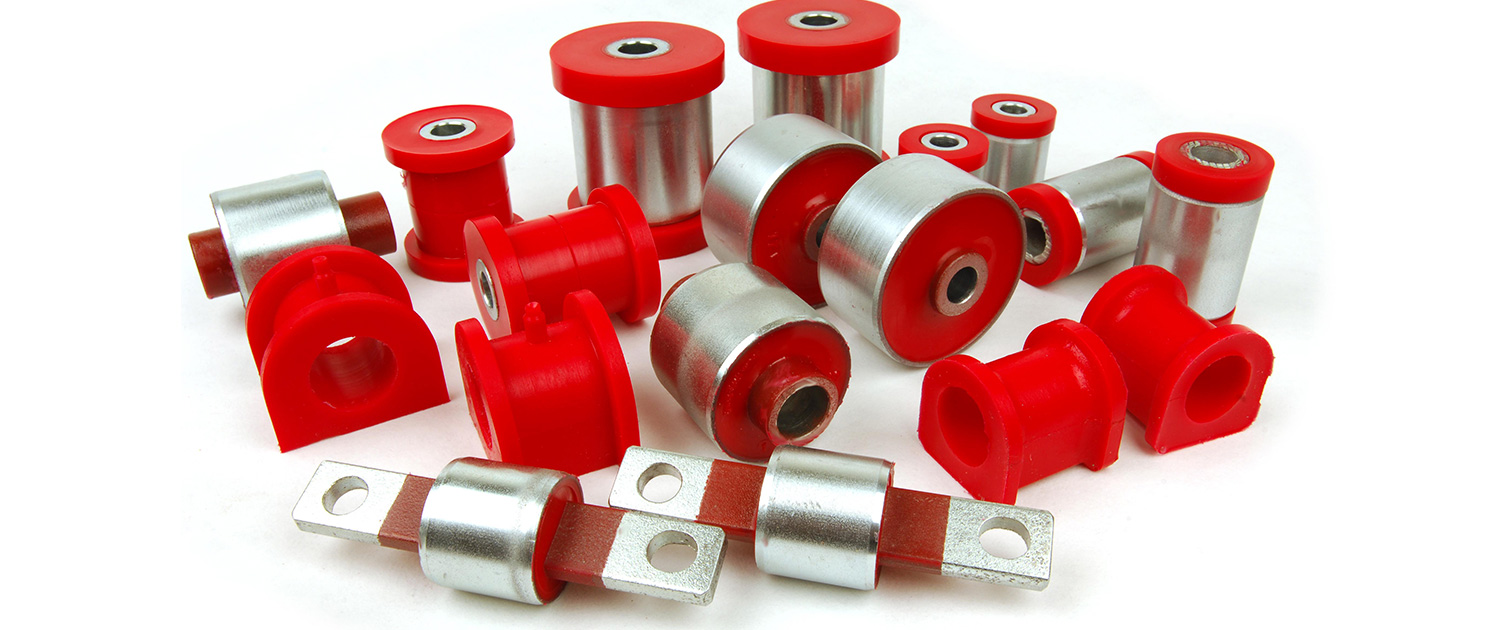

A continuous improvement exercise to re-evaluate the design and manufacture of a series of polyurethane and engineered plastic components.

Problems, Challenges

Overcoming the ‘we have always done it this way’ approach from the client’s design and manufacturing engineers.

Approach Taken

Series of design meetings were held to discuss the application of each part to ensure any improvements recommended would not affect its form, fit and function.

Problems Experienced

Educating the customer in the new manufacturing processes and materials available to implement the improvements to the components.

How the Problems Were Solved

Meetings were held with engineers and material suppliers to ensure the correct material and design changes were implemented to achieve the component cost reduction.

Results Achieved

7% cost reduction across the range of components evaluated.

Design for Manufacture (DFM) approach now in use by the customer.

Supply of components direct to production Line. KANBAN approach.

Please contact us on 01978 661478 should you require further information. Our Technical Sales Team will be happy to assist with your enquiry.