Polyurethane Bonded Mouldings

Bonaprene Products have been manufacturing polyurethane, PU, to metal bonded mouldings for over thirty years.

In this time Bonaprene have mastered the technology and necessary

high standards to produce bonds of strengths that even exceed the strength of the

Bonaprene polyurethane. The photo of the red engine mount being stretched to over 200%

of its original length indicates the power of the bond Bonaprene can achieve.

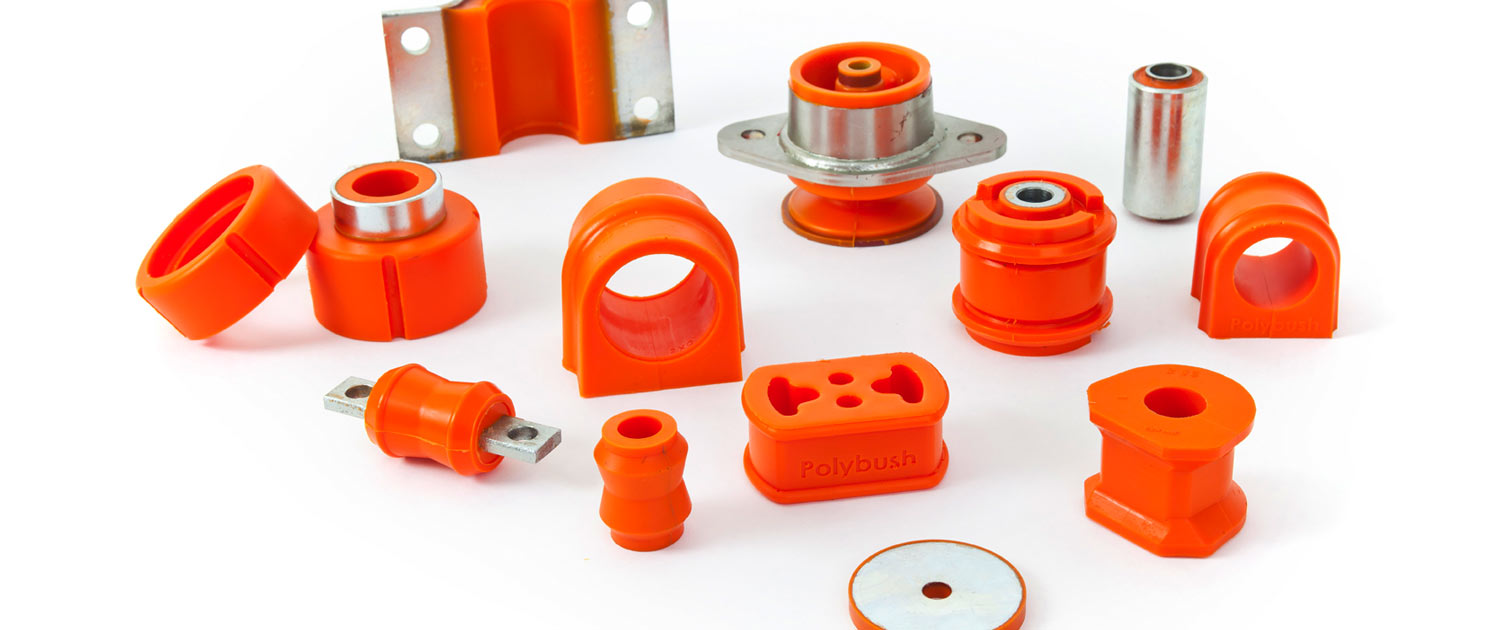

Bonaprene make many parts for vehicle suspension bushes that require polyurethane to

metal bonding where the bonds are subjected to very high torsion and compression loads.

Applications include wishbone bushes, radius arm bushes, Panhard bushes, strut mounts,

leaf spring bushes, shackle bushes, body mounts, sub frame mounts and many more.

Similar applications to vehicle suspension bushes are the bushes Bonaprene make for

reciprocating conveyors. These are conveyors with mounting arms that control the forward

thrust & re-bound strokes. the repetitive oscillating actions cause rubber bushes in the

arms to over work and melt. Bonaprene’s polyurethane bushes much higher compression

modulus & torsional strength gives a much longer lasting bush. This in turn means

operators can keep their conveyors running longer between service times.

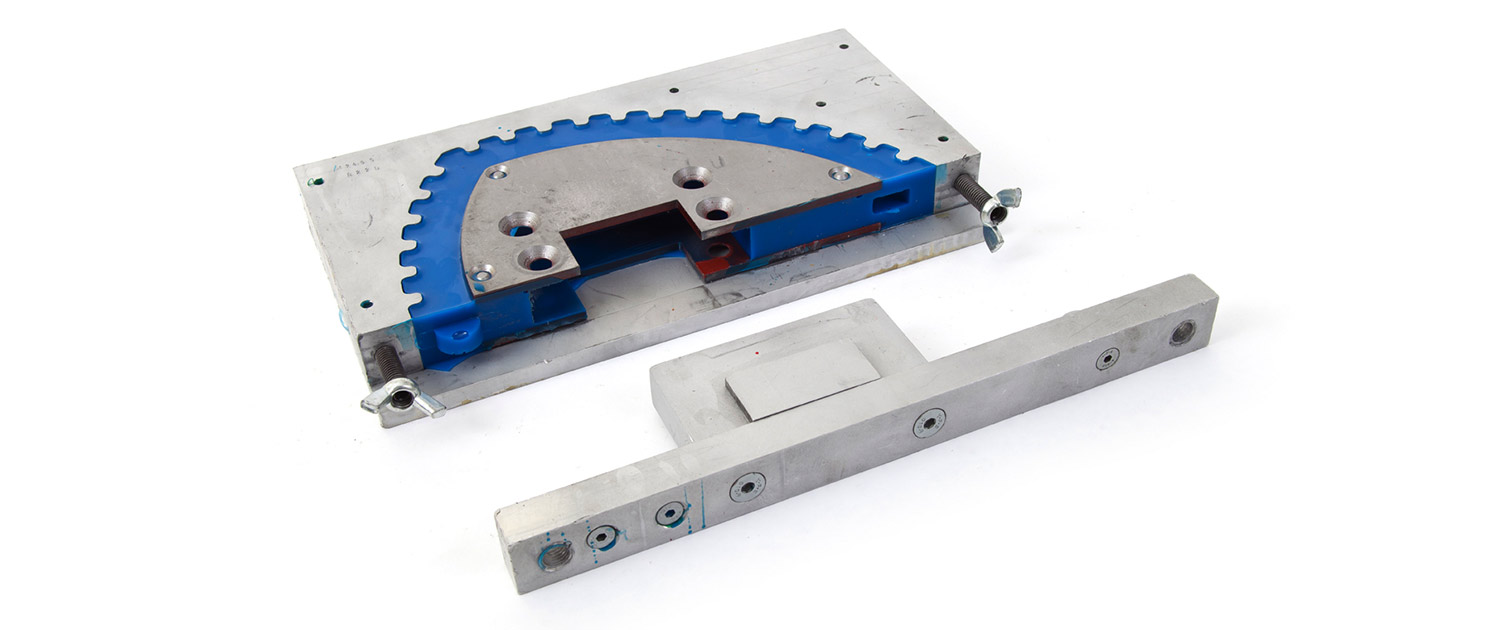

Bonaprene Products manufacture polyurethane parts with bonded in magnets. These are used

in industries such a concrete railway sleepers, concrete lintels and concrete beam manufacturing.

Here the polyurethane inserts can be easily added and removed from the concrete moulds.

This allows the concrete manufacturer to add temporary features to their concrete moulds that can

be as easily removed when the run of a particular design is complete.

Our Range of Applications Includes:

Please contact us on 01978 661478 should you require further information. Our Technical Sales Team will be happy to assist with your enquiry.